System Solutions

From single family homes to 72 story towers, Wallace Eannace can provide a turn-key solution in meeting your project’s hvac performance goals.

Whether you need help designing a hydronic system for a 51 year old, 3 bedroom house, in Riverhead or a complete pre‐fabricated mechanical room for a 72 story, new construction, high-rise in Manhattan, we have the resources to assist you from design to installation.

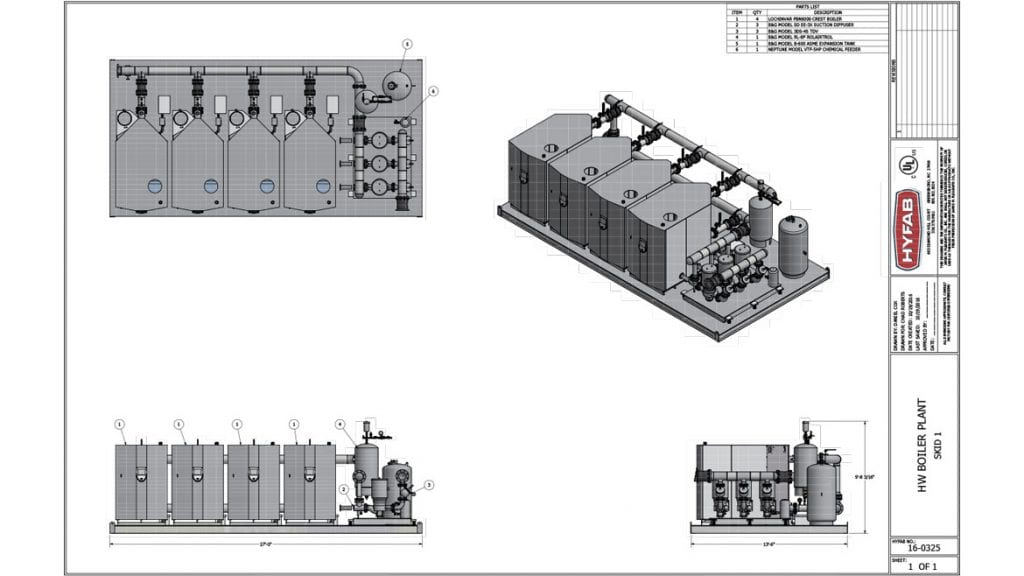

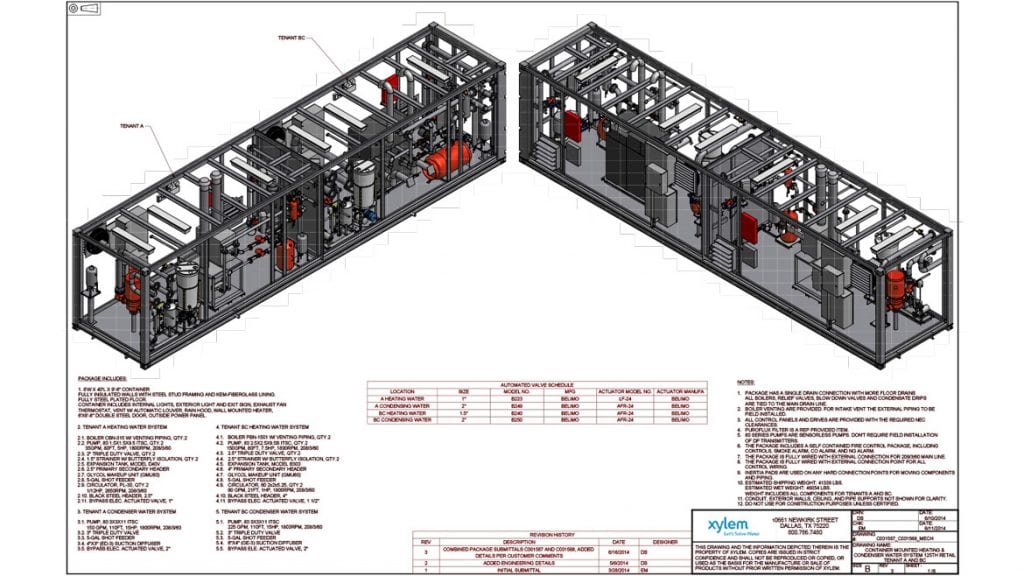

Engineered Pre-Fabricated System Solutions

Pre‐fabricated mechanical rooms require coordination of four major trades: Mechanical, Electrical, Structural, and Controls. We provide local support to the mechanical engineers tasked with designing mechanical rooms. Our support starts at schematic design and continues through installation. Providing design service to the engineering community; we interface with developers, general contractors, mechanical contractors, and wholesale distribution through the bid, sales, submittal, financing, and delivery coordination processes.

DESIGN PROJECT

Design packaged system in accordance with clients specifications

ASSEMBLE-BUILD

Construct packaged hydronic system to exact specifications and within quality controlled environment

BUDGET APPROVAL

Budget analysis, corrections and approval with the client

COMMISSION-HANDOVER

Start-up and sign off of packaged system, ensuring client expectations are met

Single Point Of Contact For Turnkey Packaged Mechanical Rooms.

How do pre‐fabricated, packaged, mechanical rooms save time and money?

Turnkey packages typically cost less than traditional construction methods. The success rests on many factors, including but not limited to: labor and quality finished product. Turnkey packaged solutions are manufactured in controlled environments. Every aspect of the build is coordinated and engineered in advance. These factors provide for high‐quality end products that save time and money during the manufacturing process. Packaged solutions are manufactured while the building is being built and arrive when needed. This coordination shortens the on‐site building time, allowing the building to be operational sooner and with high quality end-product.

Advantages:

- Mitigate risk at many levels

- Predetermined costs ensure clients stay in budget

- Reduced field construction time allows the building to generate revenue quicker

- Better coordination of trades reduces back charges

- Manufacturing in a controlled environment eliminates scheduling delays due to weather, etc.

- High‐quality end product guaranteed via coordinated, factory built packaged by skilled fabricators and tradesmen.

- Turnkey packages are pre‐piped, wired, and configured at the factory providing smooth commissioning

- Reduced footprint ‐ Turnkey packaged solutions are designed to optimize real estate

- Plug and play design reduces field labor to rigging, and connections between sections and building contact points.

- Reliable wiring & controls ‐ Assemblies ship with low and high voltage wiring complete.

- Design flexibility ‐ Custom designs allow for creative solutions.

- Single Source Responsibility ‐ providing a single point of contact from design, through bid, install, and commissioning.